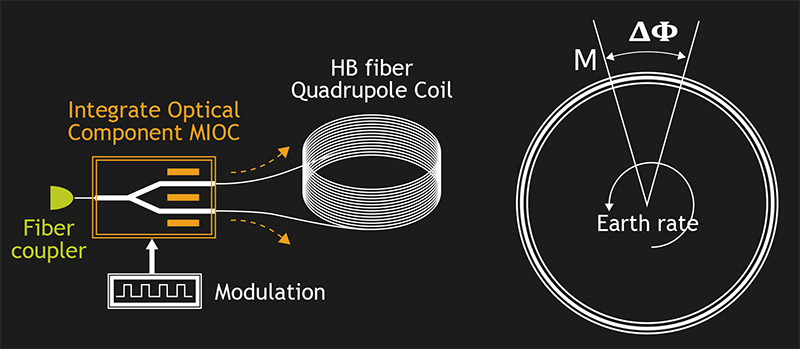

Fiber Optic Gyroscope measure the angular rotation by sending two different beams of light in opposite direction around a closed path and it precisely measure the amount of time each beam takes to return to the starting point. Rotating the coil we get a phase shift between the light beams and information in terms of angular speed. FOG outputs provides hundreds of measurements every second with outstanding precision.

GEM elettronica is a leading systems partner for the major defense agencies and industry leaders.

The most relevant benefits of Fiber Optic technology

NO-MAINTENANCE: FOG does not require any preventive maintenance;

NO-MAINTENANCE: FOG does not require any preventive maintenance; HIGH RELIABILITY: FOG has no moving parts;

HIGH RELIABILITY: FOG has no moving parts; FAST INSTALLATION: Easy to integrate and replace thanks to the compact design and Plug & Play interface;

FAST INSTALLATION: Easy to integrate and replace thanks to the compact design and Plug & Play interface; QUICK TO START: FOGs alignment time is typically only 6 minutes;

QUICK TO START: FOGs alignment time is typically only 6 minutes; COMPACT DESIGN and LIGHTWEIGHT SOLUTION;

COMPACT DESIGN and LIGHTWEIGHT SOLUTION; VERY HIGH BANDWIDTH;

VERY HIGH BANDWIDTH; ITAR FREE: All main components, including Fiber Optic Gyroscopes, are produced in house;

ITAR FREE: All main components, including Fiber Optic Gyroscopes, are produced in house; WELL-PROVEN TECHNNOLOGY: Thousands of FOGs units have been sold today in naval defence, maritime navigation, land defence and air navigation;

WELL-PROVEN TECHNNOLOGY: Thousands of FOGs units have been sold today in naval defence, maritime navigation, land defence and air navigation; ROBUSTNESS and LONGTERM STABILITY: Insensitive to vibrations, extreme shock, thermal transients and weathering temperature changes;

ROBUSTNESS and LONGTERM STABILITY: Insensitive to vibrations, extreme shock, thermal transients and weathering temperature changes; CALIBRATION FREE.

CALIBRATION FREE.

MASTERING THE ACCURACY

Inertial Navigation Systems

(INS)

GEM elettronica INS are able to provide in real time position, attitude and velocity of all types of vehicles. Coupling its state of the art Inertial Measurement Units with advanced Kalman filtering.

INS provides position, orientation, direction and speed of a moving vehicle with no need of external references.

Attitude and Heading Reference System

(AHRS)

GEM elettronica FOG-based IMUs, provide a wide range of strapdown Attitude and Heading Reference System (AHRS) able to provide autonomously 3D orientation.

AHRS systems consists of sensors on three axes that offer Heading and Attitude information for vehicle, including Roll, Pitch and Yaw.

Inertial Measurement Unit

(IMU)

Combining raw information of multiple accelerometer and gyroscopes axis, GEM elettronica Inertial Measurement Unit is the heart of GEM elettronica Inertial Systems.

IMU is able to accurately measure rotation rates and accelerations providing absolute spatial displacement of the platform on which is installed.

FROM R&D TO MASS PRODUCTION

GEM elettronica supports the development of technologies for new products, processes toward market and supply chain needs. One of the most important capability of GEM elettronica is the ability to convert innovative ideas to innovative products with world-class standard.

The quality of its manufacturing process is fundamenteal to assure a final product capable of performing outstanding precision.

GEM elettronica is the proprietary owner of all of its key FOG technologies and production process, namely the fiber winding methods, electronics and mathematical algorithms. All products are manufactured in GEM elettronica factory based in Italy. This means that we have full control of the process from the initial idea to design and production. The close relationship between R&D product development and manufacture department is a huge strength.